Blog

U.S. DOE industrial decarbonization roadmap

The DOE's roadmap, launched in 2022, targets high-emission industries like steel and cement, focusing on pillars such as energy efficiency and carbon capture to spur innovation and combat climate change.

Fred van Beuningen

May 8, 2024

In 2022, the United States Department of Energy (DOE) released its industrial decarbonization roadmap, followed by the Office of Clean Energy Demonstrations (OCED) funding announcement for industrial demonstrations in 2023. The industrial sector, responsible for a quarter of U.S. greenhouse gas emissions, is the primary focus, targeting high-emission and energy-intensive industries like iron and steel, cement and concrete, chemicals, food and beverage, and refining.

During a public meeting of the newly appointed advisory board, the four pillars of effective industrial decarbonization were outlined:

Energy efficiency

Industry electrification

Low-carbon fuels, feedstocks, and energy sources (LCFFES)

Carbon capture, utilization & storage (CCUS)

The energy-efficiency pillar focuses on reducing energy demand to cut down CO2 emissions from fossil fuel combustion. Industrial electrification aims to swap direct fossil fuel combustion with electricity, lowering carbon emissions from grid and on-site electricity generation sources. The Low Carbon Fuels & Feedstocks pillar further diminishes emissions linked to fossil fuel combustion by substituting them with low- and no-carbon alternatives. Lastly, the Carbon Capture, Utilization, and Storage pillar targets the capture of hard-to-tackle CO2 emissions directly from the source or the atmosphere, with the captured emissions either utilized or stored for longer periods to prevent their release into the atmosphere.

Embedded within a strategic framework for industrial transformation, job creation, and strategic independence, the industrial efficiency and decarbonization office is seamlessly integrated across the innovation value chain.

Decarbonization levers like circular carbon, electrification, alternative fuels, materials substitution, and alternative production methods exist across all industrial sectors, and to accelerate demonstration projects, the OCED has announced the awardees across all industries.

Driving Green Innovation: Advancements in Industrial Decarbonization

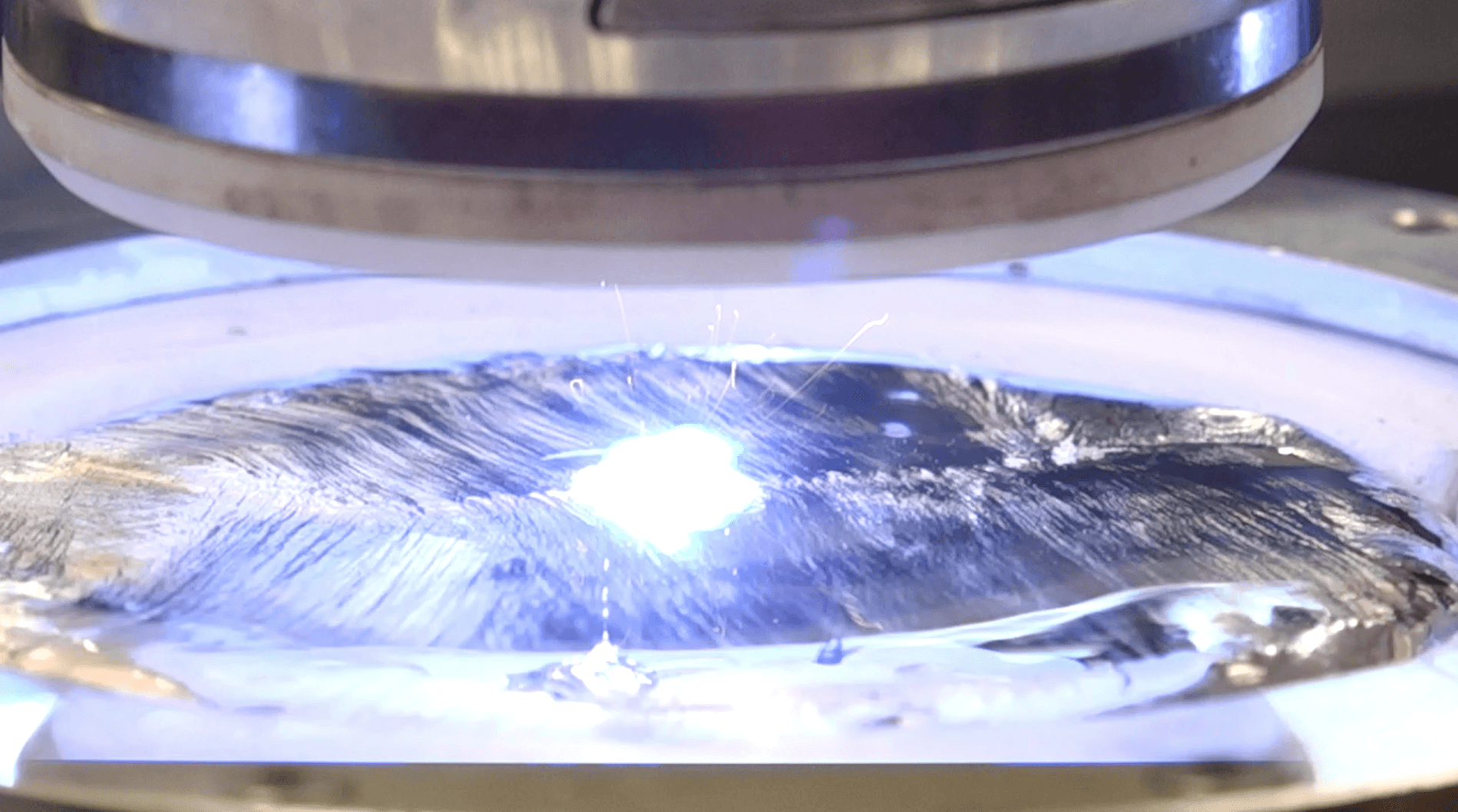

Projects like scaling green hydrogen for green steel, retrofitting cement and concrete facilities with CCS and alternative production methods, decarbonizing industrial heat through electrification and low-carbon fuels, and implementing thermal storage technologies exemplify the types of initiatives awarded funding. These projects operate under a conditional private sector cost-sharing model, aiming to demonstrate both technological and economic viability. The hope is that successful demonstrations, combined with CO2 pricing and incentives for green products, will attract further private investment.

On a broader scale, the European Commision's Net Zero Industry Act seeks to achieve carbon neutrality in Europe by 2050. This involves promoting investments in key product production capacity, establishing a streamlined legal framework for industries, and ensuring that 40% of domestic needs are met with EU-produced clean products. Despite these efforts, the first progress scorecard for the Green Deal suggests that Europe needs to ramp up its efforts, especially with competing political priorities.

Challenges and Opportunities in Transitioning to Green Steel Production

There's a push in the Netherlands to support the greening of steel production at Tata Steel, which accounts for 7% of the country's GHG emissions. Arguments in favor highlight job creation, accelerated environmental benefits, and increased competitiveness. However, some economists, like Sweder van Wijnbergen and Roel Beetsma, question the future business case and strategic autonomy for Tata Steel, suggesting that there may be better locations for European green steel production.

Traditional industrial policies prioritizing domestic industries may not align with the transition to net-zero emissions and the need for critical materials autonomy. This has led scientists to rethink the economics of industrial policy, emphasizing concepts like State Autonomy and State Embeddedness. These concepts emphasize the importance of a competent state that provides the right incentives for industries to transform while fostering institutionalized ties between industries and government to achieve negotiated outcomes.

Navigating the Path to Carbon Neutrality: Challenges and Strategies

Achieving carbon neutrality involves more than just reducing emissions; it requires addressing affordability, reliability, and industrial competitiveness. This entails shifting towards value creation through resource efficiency and cost competitiveness, offering net-zero products with green premiums, and accessing new value pools through captive demand, cheaper financing options, and new growth platforms.

Transitioning to a carbon-neutral future will necessitate technological innovation, with many technologies still in the early stages of adoption or not yet commercially available. This requires a combination of vision, public-private partnerships, innovation, and strategic planning. The time for action is now, as the window of opportunity to mitigate climate change continues to narrow.